Manufacturing data collection and monitoring.

Quickly and easily without replacing equipment or changing existing processes.

Build a Smart Factory Cloud.

Smart factory integrated management service real-time monitoring through server

Independent advance research on difficult technologies in the industrial field

Performed industry-university-research joint research project (national project)

Research on the application of new technologies and methods

Study on the localization of foreign-dependent raw materials

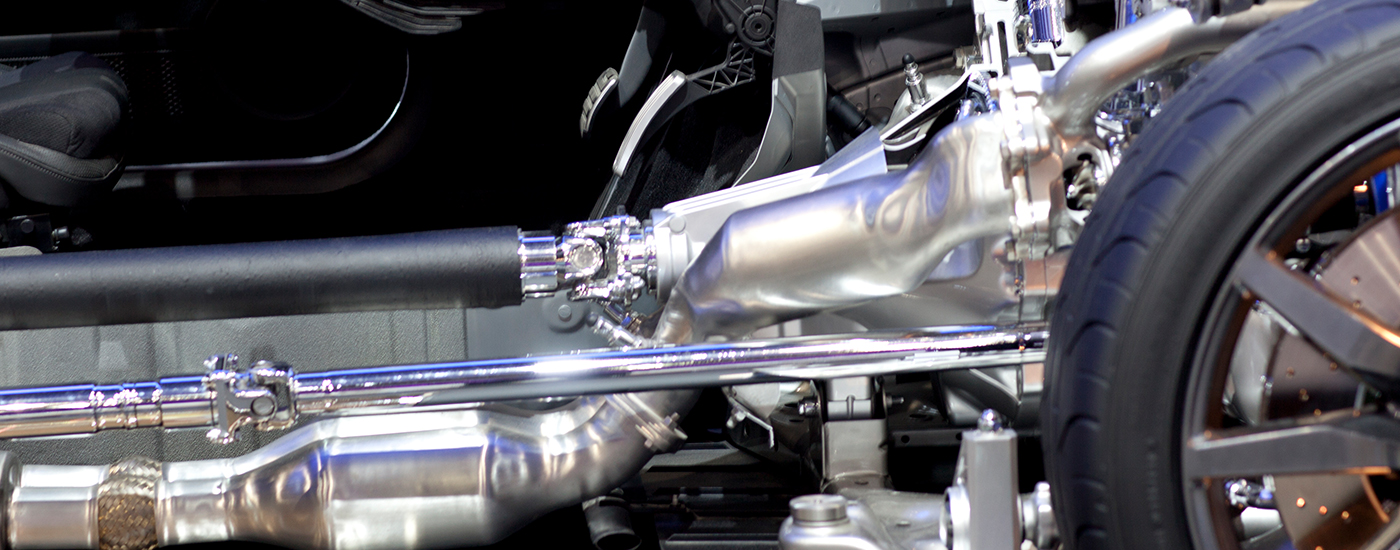

Reasonable production line construction through simulation

Jig fixture design in the preceding stage of new development

Manufacturing feasibility (machinability, quality assurance, productivity) review and problem improvement

E.C.R implementation through customer communication reduce developmenet period, saving cost, and promotes stabilization of mass production quality

Securing high-quality realization and technology by state-of-the-art facilities that can reproduce and test

Selection of solvents for strengthening cleaning power through cleanliness test and securing effectiveness of anti-rust guarantee

Maintaining “Zero” defects and improving measurement reliability by Field CMM

Material analysis (hardness, Microstructure) and defect analysis (breakage, crack, texture, etc.) → Improvement of raw material quality